Chain surface wear

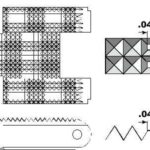

Diehl chain surfaces are completely machined with a pyramid corrugation. Once the surface on those individual pyramids reaches .025″, cutting a glue line in hardwood is not possible, and if the surfaces reach .045″, as depicted in Figure No. 5, the chain should be replaced.

Click On Any Photo For Larger View.

Figure No. 5 – Checking for Chain Corrugation Surface Wear

Chain parallelism/surface wear

Diehl chains should be interchanged every six months (based on 8 hours of daily full service) because normal wear would cause the two chains to wear in a V-pattern as viewed longitudinally. Once the chain’s V-pattern has reached .015″, a glue line is not possible, and when wear reaches .025″, as depicted in Figure No. 6, an increased probability of kickback exists, which indicates that the chains should be replaced.

Figure No. 6 – Checking for Chain Parallelism/Surface Wear

Chain Lubrication

Beginning in the late 1950’s and lasting until the pump manufacturing firm discontinued business in the early 1990’s, Diehl used a mechanical lubrication pump. Prior to this (but also including the model ESL20/25 series) the lubrication system was a gravity feed unit that wicked a felt pad, rubbing the chain on its lower return path. All of the lubrication systems work, but some have more labor involvement to insure the chain is properly lubricated. While both styles of remanufactured units are readily available from Diehl, be certain that the lubrication unit is intact and has been operative. If not, the chain may well have been damaged.